Flashings create weather-resistant seals around vulnerable areas of wall assemblies. Builders today typically choose between liquid applied flashing vs. flash tape products, assuming they comply with the ASTM D570, Standard Test Method for Water Absorption of Plastics, and the American Association of Textile Chemists and Colorists (AATCC) 127, Hydrostatic Pressure Test. Both flashing products seal gaps around windows, doors, chimneys, vents, skylights, and other fixtures of the building’s exterior.

The primary consideration when choosing fluid applied flashing vs. flash tape comes down to the ease of application of each product based on the project’s design and specifications. For both fluid-applied flashing and flash tape, leaks primarily occur due to installation error, not a product failure. Therefore, when choosing the best flashing product for your project to ensure the best protection against keeping moisture out of your building or home, Polyguard recommends you consider the flashing’s ease of installation and durability.

Fortunately, Polyguard offers several simple to apply, durable, and high-quality fluid-applied flashing tape materials: Blue Barrier™ Liquid Flashing 2100, Poly Wall®’s Blue Barrier Flash’ N Wrap 2400, and Arc Flash™ Tape.

Self-Adhered Flash Tape

The composition of flashing tape often includes a durable-flexible strip of thin aluminum (or similar substance) with a thick, highly-adhesive backing that sticks and conforms to the surrounding structure. When properly installed, robust, waterproof adhesive and self-adhered flashing tape can tightly seal gaps between the windows, doors, and around chimneys, vents, skylights, and other fixtures of the building’s exterior. Roofers also use flashing tape to seal cracks and secure shingles.

Benefits of Self-Adhered Flash Tape

- Flashing tape comes in lightweight, convenient rolls that builders can easily store and apply, providing a quick, no-mess, durable puncture-resistant sealant.

- Self-adhered flashings cover a hole or tear in the building with water-resistant tape, to stop water from entering the building.

- Self-adhered, lightweight, and flexible flashings come in different shapes and sizes, making them relatively easy to measure, bend, stretch, and fold. In addition, the uniform thickness of the rolls aids in easy measuring and application.

- When appropriately installed, the design of flash tape will accommodate the ground shifts and a building’s contractions and expansions with the temperatures and weather.

- Flashing tape comes in many sizes and colors.

Installing Flashing Tape

Flashing manufacturers typically recommend priming the substrate before installing additional sealants around the edges to ensure moisture does not get behind the flash tapes, and ensure the long-term adhesion of self-adhered flashing tapes to a substrate.

Flashing tapes come in predetermined lengths and widths, which may not perfectly fit the details of the project. However, by shingle-lapping tape pieces on top of one another (gravity lap), you can overcome the limited shapes and sizes of the self-adhered flashing.

UV-resistant flashing should avoid sun exposure past 30 days, and you should not apply flash tape in rain or temperatures below 40℉. In addition, it does not adhere well to surfaces with polysulfide.

Of concern, builders may find it challenging to apply tape to geometrically complex buildings, where outside and inside corners, recessed windows, and pipes on the building’s side require splicing, stretching, folding, and counter flashing to keep out water. You must lay the tape flat to avoid bends and wrinkles, which can diminish the tape’s adherence to the substrate and allow moisture infiltration into the wall system.

Why Choose Polyguard Arc Flash™ Tape?

Polyguard’s self-adhering, 70-mil Polyguard Arc Flash™ flash tape offers a rubberized asphalt waterproofing coating that is laminated to a stretchable, crimped, and high-strength film backing. You can use flexible Arc Flash™ products to strip in or flash straight round-top corners or custom-shaped spaces. It comes in 75-foot rolls, 6-inch, 9-inch, and 12-inch wide.

Arc Flash™ self-seals around staples, nails, fasteners, and waterproofs underneath surfaces. It adheres instantly to clean dry surfaces. In addition, its elastomeric material will stretch and maintain its integrity if a building moves.

Fluid-Applied Flashings

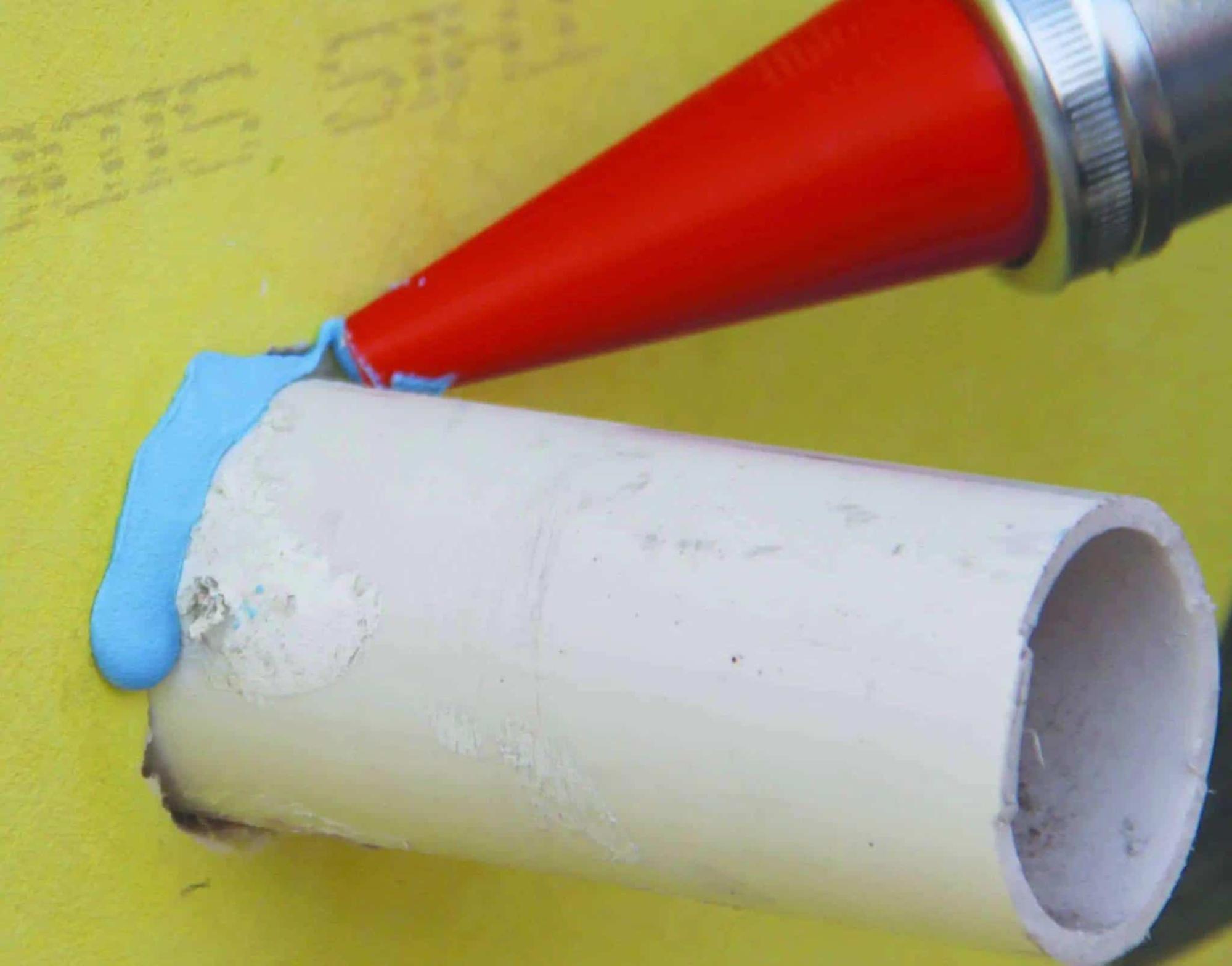

Manufacturers offer fully-adhered fluid-applied flashing in many different chemical formulations to accommodate multiple types of construction and environments. Instead of predetermined shapes and sizes, fluid-applied flashings come in sausages, cartridges, or pails.

Benefits of Fluid-Applied Flashings

- Liquid-applied flashings tie in with liquid-applied air and moisture barriers, becoming a component in a complete, monolithic system.

- Builders can quickly spread flash-applied flashings at the proper thickness to dry surfaces. However, the surfaces may require priming and have temperature restrictions.

- Fluid-applied flashing takes the shape of the substrate, regardless of the geometrical complexity, resulting in a chemical bond, creating a single monolithic membrane without wrinkles or fish mouths, ensuring long-term adhesion.

- Highly flexible liquid-applied flashings allow normal building movement, and protect against moisture intrusion.

- Fluid-applied flashing works well around window rough openings and penetration in the wall sheathing like vents and plumbing pipes.

Applying Fluid-Applied Flashing

- Clean with a damp rag or brush the rough openings and 6-inches around the perimeter of the doors or windows.

- Pre-treat cracks and holes around the windows or doors with a product like Blue Barrier™ 2200 Joint Filler, smoothing with a putty knife, and let dry.

- Apply the liquid flashing along with the head and jamb framing members. Then spread with a trowel or putty knife.

- Apply the liquid flashing around the outside of the rough opening, 4- to 6- inches wide, to a thickness that thoroughly covers the substrate (OSB).

Why Select Poly Wall® Liquid Flashing?

The design of Poly Wall® Building Solution’s two liquid flashing products (trowel and roller grade) provide the best liquid flashing, whether you need to seal around doors, windows, pipes, and penetrations or fill gaps.

Blue Barrier™ Liquid Flashing 2100 (Trowel Grade)

Blue Barrier™ Liquid Flashing 2100 creates a weather-resistant, fully adhered air barrier system around window and door installations. Poly Wall® developed Blue Barrier™ Liquid Flashing 2100 utilizing Silyl Terminated Polyether Technology (STPE), a hybrid material of silicone and polyurethane technologies. Uniting these chemistries produces an environmental-friendly, permeable liquid flashing with excellent shore hardness and superior adhesion.

Blue Barrier™ Flash’ N Wrap 2400 (Roller Grade)

Poly Wall®’s Blue Barrier Flash’ N Wrap 2400 simply applies with a roller, and produces a permeable and continuous membrane around doors and windows. Additionally, eco-friendly Blue Barrier Flash’ N Wrap 2400 utilizes STPE technology that allows for wet surface applications, does not require priming or mixing, and dries quickly. Blue Barrier Flash’ N Wrap 2400 provides:

- Durability to protect your home’s integrity

- Strong adhesion and excellent shore hardness

- High quality indoor comfort and health

Polyguard Fluid-Applied Flashing and Flash Tape

Easy to install Blue Barrier™ Liquid Flashing 2100, Poly Wall®’s Blue Barrier Flash’ N Wrap 2400, and Arc Flash™ Tape are long-lasting flashing products. They will seal gaps around doors and windows, chimneys, vents, and other components on the building’s exterior, to ensure protection against moisture infiltration.

For more on fluid-applied flashing vs. flash tape, don’t wait to contact one of our Polyguard professionals today.